Know before you overheat, not when you’re overheating

Installing a coolant pressure sensor gives you the advance warning you need to handle a coolant pressure leak and avoid a time consuming failure, or worse – a catastrophic failure like a blown head gasket that will send you and your race team packing and home early. Plus, you’ll probably avoid dumping your car’s precious bodily fluids and not turn the track into a skating rink (but you just run straight water, right?) But we digress.

Fortunately, it’s easy to add a coolant pressure sensor for real time monitoring – even real-time in the pits using RaceCapture telemetry!

Pete Pressley, team captain of Cerveza Racing – a veteran 24 Hours of LeMons team with 7 wins in about as many seasons, used a generic 150 PSI coolant pressure sensor to feed pressure data to his RaceCapture/Pro telemetry system:

“After destroying my engine at a LeMons race when a lower cooling hose popped off, it was suggested to install a cooling pressure gauge. While a gauge will work, it requires discipline to monitor, which doesn’t always happen in the chaos of a LeMons race. A benefit of the Race Capture system is that I can have the cooling system pressure highlighted in red on the app when there is a problem so that I am likely to notice quickly. The ability to measure this and watch it in the pits using the real-time telemetry feature with the addition of an inexpensive pressure sender makes it a nice enhancement that happens to be very cheap. This example also validates how easy it is to use generic pressure senders with RaceCapture. I’m planning more instrumentation such as oil, fuel and brake line pressure.”

Installation and wiring it up

Estimated time: One afternoon. Includes time for pizza and beer.

Parts list

- 10 bar / 150 PSI pressure sensor

- RaceCapture/Pro Telemetry system with available analog input port

- Wiring – Choose milspec if you want to get all serious

Sensor installation

Find a spot in your cooling system that’s convenient for the sensor installation. Since the system pressure is largely uniform (we’ll just gloss over ultra serious teams that monitor pressure at different parts of the system). Pete simply chose an available spot on the radiator of his E28 BMW race car:

In this case, Pete used a brass radiator plug and modified it by tapping it 1/8-27, then screwed in the sensor for a clean install.

Wiring

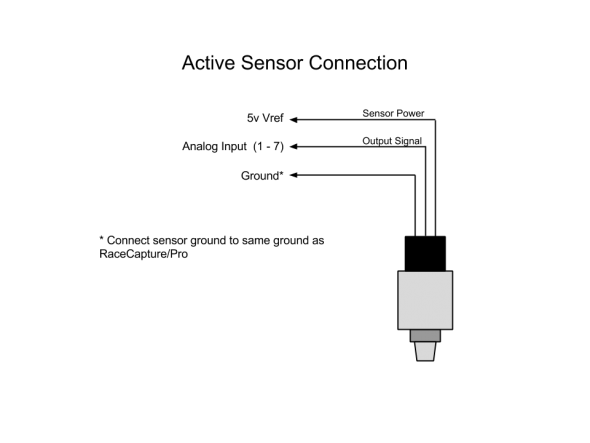

The coolant pressure sensor is exceedingly easy to wire up with 3 leads: Power, ground and signal output.

- Connect the sensor’s ground to the location where you grounded RaceCapture/Pro. If you’re into audio / classic HiFi you’ll know why star grounding is so important.

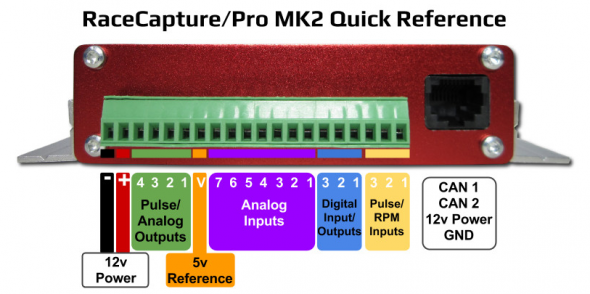

- Connect the sensor’s power connection to RaceCapture/Pro’s 5v voltage reference output.

- Connect the sensor’s output voltage to an available RaceCapture/Pro analog sensor input.

Calibration

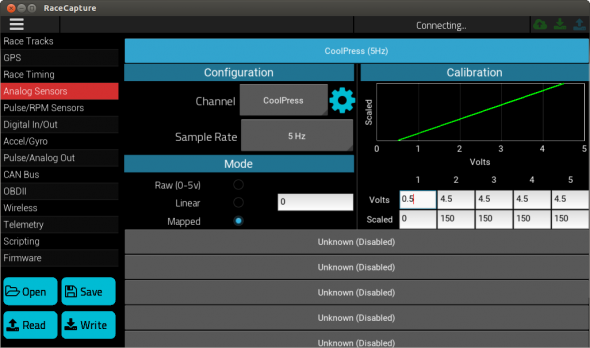

Once you have it connected to the appropriate analog input channel, set the channel calibration. Fortunately, these types of pressure sensors are extremely easy to calibrate with a linear 0.5 to 4.5v voltage output across their rated pressure. So, for a 150 PSI sensor (10 bar metric equivalent) you’ll observe:

0.5v = 0 PSI (0 bar)

4.5v = 150 PSI (10 bar)

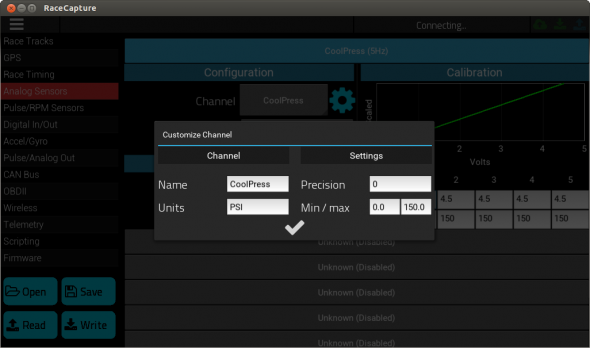

Configure the RaceCapture/Pro analog input setting as follows. Note the Mapped Mode and channel mapping table:

Customize the channel by touching the gear icon next to the channel name:

Once the configuration is set, write it back to the RaceCapture/Pro. (and save your configuration for safe keeping!)

Verification

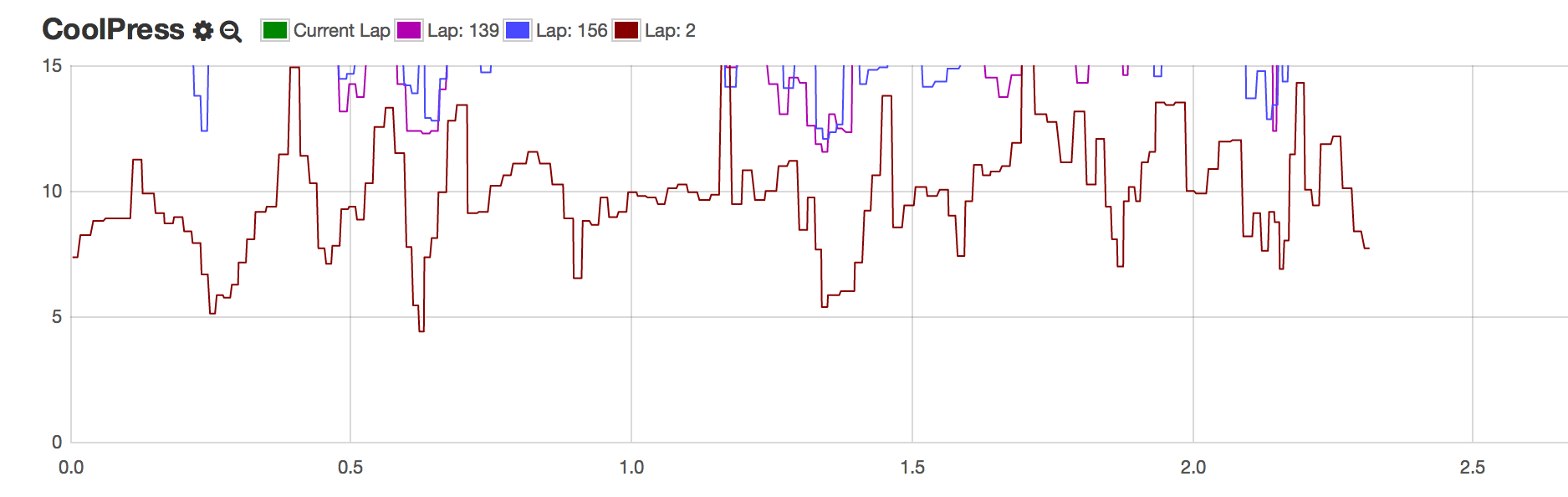

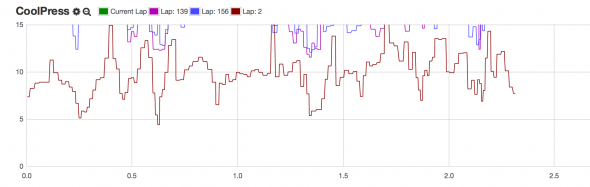

While the engine is running, switch to the dashboard mode, configure a gauge with alert colors, or simply monitor it on the raw channels view. Here’s a demo video after Pete completed his installation:

Improving your Race Craft

With RaceCapture telemetry, you get much more than an in-car dash or after the fact analysis – you can track your car’s data in real-time, while it matters – during your race.

You’ll also uncover fascinating information about what your race car is doing during the race, and you’ll be able to correlate information, see trends and compare changes in setup.

Tell us your sensor ideas and battle stories

What happened to you during a race where additional knowledge / data would help? Comment here and tell us about your battle scars – and what additional data would help.

Hi

I am interested in adding a coolant pressure gauge to my car,my rad is a typical

sbc radiator,that doesn’t have a port access like the one shown in your car.

Can i use the water pump as a source of coolant pressure,via the heater box port on the w/p

housing,and if so what psi will i see,or is there another alternative source.

I don’t want to split the rad hose and add an adapter ,please advise as i will consider all

options.,how about using the coolant port boss on the intake manifold,will this

be at the same press. as the rad press.

Thanks

Since the cooling system is a closed system, you can connect it anywhere in the loop. it does not matter if it’s before or after the thermostat. If you find a convenient place to tap a port for the sensor, I’d say go for it.

-Brent

Hi Brent

Thanks for the advise on the pressure sensor question.

I have another question,and it is as follows ,I’m thinking of moving the coolant ( too hot ) sensor for an indicator light,to the top of the radiator core.

I’m using a probe style sensor,will the temp. on the coolant transfer through the copper

metal frame on top of the rad. core ,through thermal radiation and will the sensor read this

heat in that spot ( near the upper rad hose).

I am doing this to clear the coolant sensor port on the intake manifold for the pressure

sensor.

Please advise if this will work,or is my original plan of incorperating 2 sensors via a T fitting

on the same coolant port.

Thanks again!!

the sensors always perform better when they are immersed in the cooling liquid. I would keep that approach however you can, versus a sensor attached to the outside of the radiator.

Hi Brent

If I understand your reply,is that by using a T fitting

and as long as the eng. w/p keeps circulating the coolant that the sensors for pressure and temp. will

work.

How about what type of material will work best with

an aluminum int. manifold?

Thanks for your quick response.

The type of metal you use is not critical. Use what’s convenient.

Hi Brent

I have another question regarding my 1978 buick century,i have a saginaw 605 p/s system

and thinking of installing a pressure gauge to read the p/s system pressure on the h/p line

of course.Can I use a nitrous press. gauge 0-1600 psi to read this,since there are no specific

gauges for this,will the sensor be o.k. with hyd. oil fluid rather than nitrous gas ,also same thing with the brakes hyd. pressure.

Please advise,and thanks!

Don’t know. Just make sure the sensor you’re using is compatible with the media involved, to ensure the sensor isn’t damaged

Hi Brent

Thanks for the tech. info.!

My gauge will be 0-35 psi indicated on the gauge ,so if my car has 16 lbs rad cap

when system coolant reaches 16 psi the rad cap should protect from going over that figure.

So gauge should show when system is hot 16 psi or so?

Quite possibly!

Appreciate the article and insight into using pressure sensor for the leak detection.

As a baseline/threshold what exactly are you using to trigger air-in-the-loop? Is this something you calibrate after inducing air-in-the-coolant?

Depending on the piping network, throughout the coolant loop, the nature of the flow (i.e. turbulence, turning back on itself, and further type of air entrainment) are often pretty variable… so just curious how that threshold level is set (I’ve heard of the NPSH_r level being a trigger point as onset of cavitation, air entrainment show pretty similarly)

It is not terribly scientific. The process is to determine a baseline pressure for normal operation – deviation outside of that norm would be the tell if there’s leakage within the system. Also, it would be a combination of pressure at a specific temperature, of course.